|

BRHS /

Global Agreements on Road VehiclesChapter 7. Legal Requirements, Standards, and other CodesList of Contributors

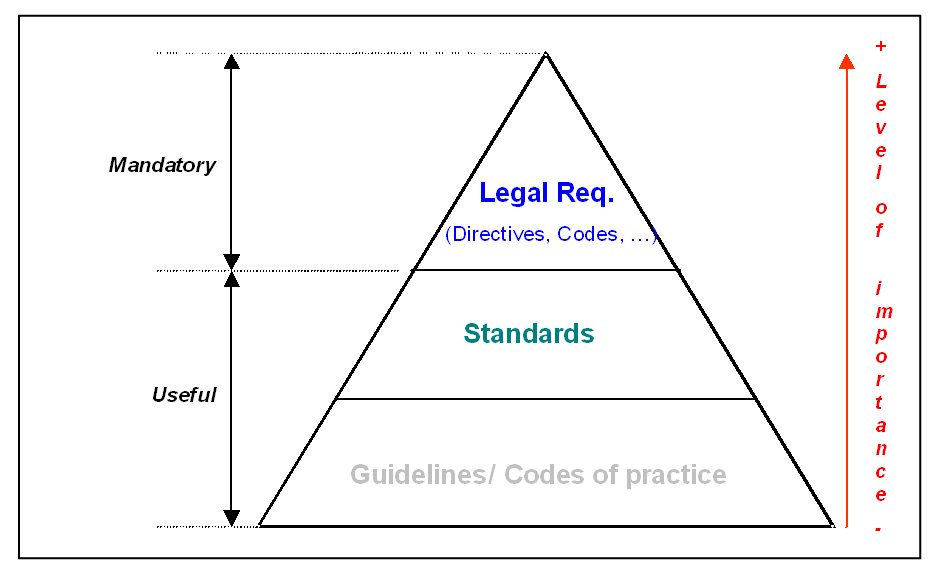

DefinitionsGeneral Figure 1. As shown in the figure above, the main difference between legal requirements and standards is their legal status. Legal requirements are made by political bodies (parliaments, governments), they are legally binding, and prescribe an acceptable level of, for example, safety or emissions for the technology in question. In contrast following standards are voluntary, but they are a useful instrument for the industrial organisations or interest groups dealing with the technology in question. Persons looking for technical advice will probably find it rather in the documents of lower legal rank. The task of parliaments or governments is not to think about a suitable wall thickness or the necessity of burst disks but rather to care for the legal framework. Legal RequirementsA legal requirement (directive, regulation or code, etc.) is a local, national, regional (e. g. European), or supra-national (e. g. UN ECE) statutory text which is imposed by a legal authority. It states requirements that are written and adopted by legislative bodies, so as to regulate a particular kind of activity. Legal requirements are intended to ensure that a product or system or activity will not impact on the human safety / health or on the environment. StandardsA standard as discussed in this report is a document, established by consensus and approved by a recognised body (Standard Drafting Organisation – SDO), that provides, for common and repeated use, rules, guidelines or characteristics for activities or their results, aimed at the achievement of the optimum degree of order in a given context. An international standard is a standard developed and adopted by an international standardisation organisation (like ISO or IEC) and made available to the public. The application of a standard is not obligatory, unless a regulation refers to that standard. Even then the legal power comes from the regulation, not from the standard. DistinctionThough standards and regulations are frequently mentioned together it should be remembered that they are two fundamentally different concepts. While regulations are mandatory for everybody in its domain, standards are not. Standards facilitate the trade and use of goods or services. Their main role is to make components or services fit together: pressure cylinders with valves, valves with regulators and further equipment leading the gas to the place of use. This, however, also involves safety issues, and so there is of course an interface with regulations. The following table highlights the most important characteristics of legal requirements and standards:

OthersCodeIn legal terms, a code is a collection of rules, requirements or standards that have been made binding and mandatory by a local or national government (as defined in the ISO / TR 15916). They are frequently proposed by recognized public or private bodies for the benefit of the relevant authorities. In practical use of language the term code often refers to a North American document. In this report, we distinguish “code” (with compelling power) and “code of practice” (which is a voluntary instrument – see paragraph 6.1.5.2 “Code of practice”). Code of practiceCodes of practice are usually a set of best practices for a specific product or system so as to ensure safe handling, maintenance and operation. Codes of practice are usually developed by industry specific organisations. GuidelineA guideline or a guide is a document generally written for a given organisation, whether for its own needs, or for its customers’ needs. Guidelines provide guidance to appropriate behaviour so as to ensure safety of people (workers, users and general public). It may also give information about codes, standards and regulations to comply with and about the recommended way to meet those requirements. For example, it gives information related to material properties, adequate installation, use of equipment and safety procedures. Guidelines may be aimed at:

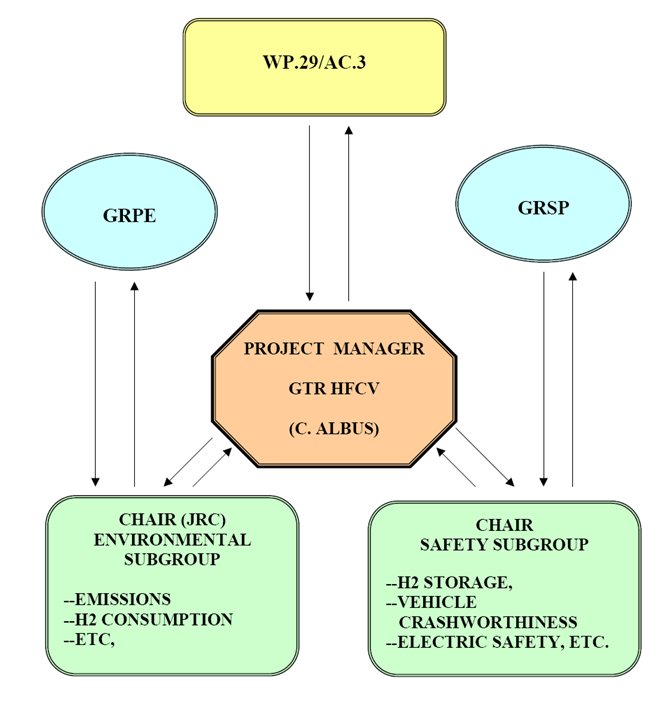

Of particular importance are guidelines in the framework of the European Union where they give a compelling basis for the harmonization of the national laws of the member states in a certain field. This and examples of relevant guidelines will be discussed in detail under item 6.3 “Regulations”. State of the artState of the art is a term rather than a type of document and is the most advance technique or method used at a given time. Best engineering practiceBest engineering practice is a term but may also refer to a document and means the best practices performed in the design, construction, or operation of structures, machines, or other devices of industry and everyday life. Best engineering practices are defined from the industrial organisations and key implementors of a given technology. Global Agreements on Road VehiclesGeneralTo facilitate global commerce in road vehicles it has long been recognised that there is a necessity to harmonise regulatory requirements across the major markets. These activities were initially undertaken on a European level by WP.29 a subsidiary body of the United Nations, Economic Commission for Europe, Inland Transport Committee, but that role has now expanded to a global one. WP.29 was originally titled Working Party On The Construction Vehicles but latterly has been renamed World Forum For Harmonisation Of Vehicle Regulations. UNECE 1958 Agreement (Regulation)In the framework of the United Nations' Economic Commission for Europe (UNECE) in Geneva, and for mobile applications, WP.29 and its subsidiary bodies are developing Regulations under the 1958 Agreement in cooperation with all Contracting Parties to the Agreement and non-governmental organizations (NGOs). The 1958 Agreement is entitled “Agreement concerning the adoption of uniform technical prescriptions for wheeled vehicles, equipment and parts which can be fitted and/or be used on wheeled vehicles and the conditions for reciprocal recognition of approvals granted on the basis of these prescriptions.” UNECE Regulations are not applicable on a mandatory basis to all Contracting Parties to the 1958 Agreement, but if a Contracting Party decides to apply a UNECE Regulation, the adoption becomes a binding act. A contracting party that has adopted a Regulation under the 1958 Agreement is allowed to grant type approvals pursuant to that Regulation and is required to accept the type approval of any other contracting party that has adopted the same Regulation. European and some non-European countries, require an authority together with a technical service undertaking approval testing, to assess compliance of components and the vehicle with the legal requirements. The process is known as type approval. In contrast North America uses the self-certification process. For instance, the Regulation 110 is an example of UNECE Regulation under the 1958 Agreement; it is related to the “uniform provisions concerning the approval of: I. specific components of motor vehicles using compressed natural gas (CNG) in their propulsion system ; II. vehicles with regard to the installation of specific components of an approved type for the use of compressed natural gas (CNG) in their propulsion system.” The 1958 Agreement was revised in 1995 (Revision 2) to promote the participation of non-European countries and became a global agreement. The United States did not adhere to this Agreement. Members of the 1958 agreement are: Germany, France, Italy, Netherlands, Sweden, Belgium, Hungary, Czech Republic, Spain, Yugoslavia, United Kingdom, Austria, Luxembourg, Switzerland, Norway, Finland, Denmark, Romania, Poland, Portugal, Russian Federation, Greece, Ireland, Croatia, Slovenia, Slovakia, Belarus, Estonia, Bosnia And Herzegovina, Latvia, Bulgaria, Turkey , The Former Yugoslav Republic Of Macedonia, European Community, Japan, Australia, Ukraine, and The Republic of South Africa. UNECE 1998 Agreement (Global Technical Regulation)Global Technical Regulations (GTR) apply to road vehicles with the aim of developing globally harmonised technical requirements. GTR contain technical requirements and are established under the 1998 Agreement ("Agreement concerning the establishing of global technical regulations for wheeled vehicles, equipment and parts which can be fitted and/or be used on wheeled vehicles", done at Geneva on 25 June 1998). GTR are different from the EU Directives and UNECE regulations because they do not call for mutual recognition of type approvals or certifications; they permit existing approval procedures to be utilized by harmonizing only the technical requirements. The 1998 Agreement allows all regions of the world to participate in the development of GTRs for vehicles and their components. Canada, China, EC, France, Germany, Italy, Japan, Korea, the Russian Federation, South Africa, Spain, the UK and the USA are included in the contracting parties to this Agreement. UNECE WP29 GRPE Draft ECE “´58 Agreement” RegulationsWork on proposals for harmonised hydrogen vehicle regulations for Europe was initiated in 1998 by the European Integrated Hydrogen Project (EIHP) . After a survey of existing regulations identified none applicable directly to the use of hydrogen in vehicles, EIHP initiated the process of developing initial proposals for new, flexible harmonised regulations. The draft proposals were based as far as possible on performance requirements rather than historical technical solutions with the aim of encouraging rather than restricting the development and introduction of safe, new technologies. Various analyses were undertaken by the EIHP partners to provide a base from which to develop draft harmonised regulations. For the basis of the draft harmonised regulations, EIHP chose United Nations’ Economic Commission for Europe (UNECE) “ECE” Regulation as at that time Global Technical Regulations (GTR) were not possible. Additionally the ECE was the drafting body for related alternative fuel regulations for CNG and LPG. Due to differences in the technologies between compressed gaseous hydrogen (CGH2) and liquid hydrogen (LH2) storage, two drafts were developed. The drafts cover vehicle storage, on-board refilling and fuel supply components and installation of the components/systems within vehicles. A primary objective of the regulations was to avoid defining technical solutions by developing performance requirements. In a similar manner efforts were made to avoid limiting the development of future hydrogen technologies, e.g. by avoiding specifying upper limits for CGH2 storage pressures. The aim of the draft regulations was to enhance the safe and economic manufacture and use of hydrogen fuelled vehicles. Validation of the draft hydrogen regulations was an ongoing process. A workshop was held in 1999 to discuss the basis of the draft regulations, to which representatives were invited from national authorities, industry and research institutions. Subsequently comments on the proposals were obtained from national authorities and external experts which were integrated into the proposals. The continuous development process was continued into EIHP2 and resulted in a number of iterations until wide consensus was achieved. In particular the gaseous hydrogen draft was heavily revised to avoid difficulties experienced during the certification of CNG components/vehicles to ECE R110. Additionally the draft resulting from the first phase of EIHP was further validated within EIHP2 by following the test and approval procedures for storage vessels and the installation of the associated hydrogen system onboard vehicles by BMW and DaimlerChrysler. The proposals were presented to UNECE WP29 in 2001 and were subsequently forwarded to the subsidiary group, Working Party on Pollution and Energy (GRPE) which established an ad-hoc or informal group to coordinate the further technical development of the drafts and to achieve wide international consensus. The informal group is now known as Informal Group “Hydrogen/Fuel Cell Vehicles” (IG-HFCV) and was integrated in the H2FCV sub-working group environment. Work included harmonisation meetings with ISO experts developing standards with similar scopes. The scope of the draft ECE regulations includes the hydrogen storage, refuelling and fuel supply components and systems, and their installation within a road vehicle as OEM equipment but excludes, for example, the fuel cell system. The draft ECE LH2 regulation was introduced as a formal working document at the GRPE in 2003 together with latest amendments . The draft ECE CGH2 regulation was introduced as a formal working document at the GRPE in 2004 together with latest amendments . During 2005 UNECE WP29 took the decision not to proceed with ECE Regulations for hydrogen vehicles and instead develop a completely new GTR. UNECE WP29 GTRDuring 2005 UNECE WP29 took the decision to proceed directly to a completely new GTR and initiated development work following support from the major markets of Europe, Japan and USA amongst others. Authorities and manufacturers in all major countries or regions including Europe, North America and Japan have agreed that long term legal requirements for the use of hydrogen in motor vehicles should be based on Global Technical Regulations (GTR) under the UNECE WP29 “1998 Agreement”. A GTR contains technical requirements but allows compliance to be “approved” in accordance with the normal system of each country, i.e. type approval or self-certification. The work is being undertaken by the Informal Group “Hydrogen/Fuel Cell Vehicles” (IG-HFCV) co-sponsored by Germany, Japan and the USA, see diagram below. Despite universal agreement on the ultimate aim of GTR for hydrogen vehicles, there are still significant open discussions regarding the scope, underlying philosophy and detail of such a document. Hydrogen GTR are planned to be in place by the end of 2010, though this is a very ambitious timescale. The current roadmap to the introduction of a GTR can be seen at: http://www.unece.org/trans/doc/2005/wp29/WP29-136-24e.pdf.  Figure 2 Regulations - GeneralGeneralHandling flammable, compressed, or cryogenic substances may be dangerous not only for the person doing it but also for others or the society as a whole. Industrialisation brought about not only much larger amounts of such substances used for processes of all kinds but also a more complex structure of the society which is more vulnerable from technical problems. This is why for the last two centuries more or less all countries (or their provinces or communities) issued legal requirements or regulations in order to guarantee a minimum level of safety for human life and health as well as for material values. The increasing safety demands of the modern citizen towards the society, new technologies (nuclear, genetic) as well as new threats (terrorism) cause an ever increasing refinement of those rules. This paragraph deals in particular with legal requirements applicable to hydrogen and the safety issues associated with it. The purpose of the legal requirements discussed here is at first to prevent damage to persons working with dangerous substances. This does not primarily mean somebody who handles them privately for his own purposes. It is rather directed at somebody who handles something by order of his employer. Here the rules for dangerous substances in a commercial environment place the responsibility on the employer or the direct superior of the worker by demanding a certain level of technical equipment, education and information providing a reasonably safe process. Nonetheless any damage which might occur must not become so major that it affects the general public outside the working place or company. Another important field for legal requirements is the transport of dangerous substances. Persons involved not in the handling of the substance, but only in their transport (like truckers or railway workers) shall be protected from undesirable effects, and the same holds for the general public. What is true in each individual country applies also to a body like the European Union. Neither the European Commission nor the European Council or the European Parliament, however, can simply sidestep the sovereignty of the member states in replacing their national regulations by others. Though there are European regulations (which require the consent of the European Parliament and the European Council), the man instrument for achieving a common ground in all countries are directives. They define a certain level which is compelling, but not immediately for the individual citizen. Directives are rather directed to the member countries which are obliged to adopt them in their national legislation within a reasonable time. In doing so the national legislation has a certain manoeuvring space, but only to one side; the minimum level given by the directive must be maintained. Apart from the directives of the EU there are also other regulations from other sources. International transport of dangerous goods is dealt with in a number of international agreements which comprise ADR (road), RID (rail), IMO (sea) and ADNR (inland waterways). ADR and RID are also relevant as EU regulations because they are annexed by the Council Directives 94/55/EC and 96/49/EC, respectively. Air traffic is cared for by IATA and ICAO. For making sure that motor vehicles can be used internationally there are different provisions; one of them involves the UNECE. European Legal RequirementsEuropean laws, such as Directives, Regulations, European rules prevail over national laws. In order to carry out their task and in accordance with the provisions of the Treaty establishing the European Community (the EC Treaty), the Parliament acting jointly with the Council, the Council and the Commission make regulations and issue directives. European Directive (art. 189 of the EC Treaty) A directive shall be binding, as to the result to be achieved, upon each Member State to which it is addressed, but shall leave to the national authorities the choice of form and methods (national transcription). Regulation (art. 189 of the EC Treaty) A regulation shall have general application. It shall be binding in its entirety and directly applicable in all Member States. The EU has for example submitted a first draft of a regulation for the type approval of hydrogen vehicles for discussion. The requirements of a European directive are brought into force by enacting national legislation in the EU member states, whereas a European regulation is effective without national implementing legislation. There is, of course, no such thing as a European Hydrogen Directive. Apart from a few exceptions for very important or particularly dangerous substances regulations are usually not substance specific, but application specific. So the correct question is not: “Which regulations apply to hydrogen?”, but rather: “Which regulations apply to what I want to do with hydrogen, and to the environment where I intend to do it?” It is possible to distinguish between the following Directive typologies under the EC Treaty:

Among the most important European directives applicable to hydrogen are those on pressure equipment. There are the Pressure Equipment Directive (PED) and separately the Transportable Pressure Equipment Directive (TPED). The latter is closely connected to international agreements on the transport of dangerous goods (ADR, RID, …). Another important field of regulation when flammable gases are involved is the prevention of damage by explosions in case the gases are released unintentionally. This is mainly covered by the directives 94/9/EC (formerly ATEX 100) and 99/92/EC (formerly ATEX 118). Prevention of major accidents and associated releases of harmful substances in the environment or the mitigation of the effects, respectively, is the subject of the Seveso II directive. While these are the most important and specific ones there are numerous directives which might be applicable in a certain context or situation. The Machinery directive is an example for a document of very general character which applies to almost anything, including hydrogen technology. The more important directives will be discussed below in detail. New Approach Directives and Harmonised StandardsThe European Union introduced a series of measures to ensure the free movement of goods throughout the European Union (EU) and the former European Free Trade Association (now part of the EEA). New Approach Directives are one of these measures. These Directives aim at controlling product design and above all, at ensuring technical harmonisation of product safety requirements across Europe, so as to guarantee a high level of protection to the public. The New Approach has been laid down by the Council Resolution of 1985. European harmonised standard provides the detailed technical information enabling manufacturers to meet the essential requirements. "Harmonised Standard" has a specific meaning in the context of the ECs “New Approach” to regulation:

A harmonised standard provides a presumption of conformity with the essential requirements covered by the standard. These standards - produced under a mandate from Member States through the Commission - give the technical measures to meet the essential requirements. The Guide to the implementation of directives based on the New Approach and the Global Approach defines essential requirements as follows:

The New Approach Directives also explain to the manufacturers how to demonstrate conformity with the essential requirements. Products which meet the essential requirements are to display the CE marking, as described in the particular directive. CE marking means that the product can be sold anywhere in the Community/EEA . When a product bears a CE marking , it means that:

Application of harmonised standards or other technical specifications remains voluntary, and manufacturers are free to choose any technical solution that provides compliance with the essential requirements. (source Guide to the Implementation of Directives Based on New Approach and Global Approach – European Commission). The following Council Directives are based on the New Approach principles:

CE MarkingThe CE marking is neither a mark of origin nor a quality mark. CE marking applies to the manufacturer who has to affix the marking to state the conformity with all applicable directives. In details CE marking shows that the product marked fulfills all applicable provisions (or requirements) of applicable directive(s) that provide for CE marking (essential requirements, harmonised standards and specific dispositions), and that the product has been subject to the appropriate conformity assessment procedure(s) contained in the directive(s). The scope of the CE marking regime is laid down in the relevant harmonisation directive(s), and can only be apllied by the legal entity responsible for the conformity of the product. The hydrogen system shall comply with the following directives in order to gain CE marking :

The most relevant EC requirements are discussed in the next paragraphs. Major Hazard DirectiveContextSeveso is a city near Milan in Italy and was the site of one of the most consequential accidents in chemical industry in 1976 when a great amount of dioxin was released into the air by a nearby plant. Triggered by this event European Economic Community Members decided to reinforce regulation on industrial activities. That's why the SEVESO I Directive was elaborated the 24 June 1982 to avoid new accidents such as this one and why it got this name. But new accidents imposed new reflections on developing new actions. Due to the low efficiency of the regulations, the European Union Council decided in 1987 to deeply modify them. A new Directive called "SEVESO II" was adopted in 1996 (96/82/EC) instead of SEVESO I. The Amendment of the Seveso II Directive adopted by the European Parliament and the Council on 16 December 2003, was the following of Toulouse accident (France - 21 September 2001), Baia Mare accident (Romania - January 2000) and Enschede accident (Netherlands - May 2000). Enforcement field and subjectThe last modifications of the Directive concerned the field of the regulation : First of all, the notion of plant has as consequence that substructures as rail junctions, docked boats and wharf are now concerned, contrary to pipelines, ports or railroad-yard which are not concerned. Then, the thresholds of some substances were changed and more activities were concerned (mines, chemical or thermal stones treatment, potassium nitrate and dangerous substances for the environment, carcinogenic goods). Modalities of elaboration for internal rescue plans and the consideration of distances between important tracks of transport and leisure areas for urbanisation control were introduced. Concerning other obligations, domino effects have to be studied (are the consequences and probabilities of failures more important because of the location of equipments and dangerous goods?). Information has to be exchanged between companies about these domino effects. The consideration of urbanisation control should allow to impose safety perimeters for existing plants and impose additional technical measures. The Directive also emphasises the policy of prevention of major accidents and obliges industrials to write a document, which explains this policy and makes sure it will be applied. The Directive introduces, for each substance, a lower and a higher threshold. The plants that are beyond the higher threshold present high risks. High risk companies have to demonstrate in a safety report their policy of prevention of major accidents and have to develop and implement a safety management system. Besides, they have to inform population on their risks. Place of hydrogen in this regulationHydrogen is concerned by the Directive; it is indicated in appendix I. The lower threshold (column 2) is 5 tons and the higher threshold (column 3) is 50 tons. Since the appearance of the Directive, each country has transposed this European regulation in National regulation. IPCC DirectiveContextThis Directive No. 96/61/EC of the Council of September 24th, 1996 is about the prevention and integrated reduction of the pollution (Official Journal of the European Communities n° L 257 of October 10, 1996). The Directive was modified lastly by the Directive 2003/87/EC of the European Parliament and of the Council of 13 October 2003 establishing a scheme for greenhouse gas emission allowance trading within the Community (OJ of the European Communities n° L. 275 of October 25 2003) Enforcement field and subjectThe IPPC Directive is one of the mainstays of the EU legislation on the environment together with the SEVESO II Directive. It's based on the issue of operation permits to control incidents of the activity on the environment. The Directive applies to a great number of activities, mainly industrialist which present high risks of pollution, for example in the sectors of energy, metallurgy, mineral and chemical industry, waste management and food-processing industry. It also applies to intensive breeding. The list of the activities affected by the Directive appears in appendix I. Its objective is to prevent and reduce the pollution of air, water and soil thanks to a global system of authorisation which considers these three compartments simultaneously. The Directive also covers waste production, energy use, accidents prevention and cleaning of the factories site. This approach insures a high degree of environmental protection and is different from the former environmental regulation which dealt with each compartment individually. Limiting factorsSites affected by appendix I of the Directive have to obtain an operation permit in order to ensure protection against air, water and soil and to reach a high level of protection for the whole environment. The permit can be updated. The Directive plans the participation of the public in the decision-making process towards the issue of the permit. The permit must fix limits of emissions for the substances affected in appendix III of the Directive. Place of hydrogen in this regulationThe chemical installations intended for the manufacture of basic inorganic chemicals such as hydrogen are affected by appendix I of the directive on IPPC, and therefore must be operated after a permit is issued. Hydrogen generation on site (for example at filling stations) may cause interpretation problems because strictly legally the directive includes also very small hydrogen generation units like small electrolysers or reformers which generate little or no pollution even though its meaning is clearly intended at large plants. ATEX DirectiveATEX directive 1999/92/EC is about minimum requirements for improving the safety and health protection of workers potentially at risk from explosive atmospheres (ATEX). Hydrogen is a flammable gas which can form an ATEX where mixed with air (such an ATEX is defined by the directive as a mixture in which, after ignition occurred, combustion spreads to the entire unburned mixture). An employer who runs facilities where hydrogen is processed has the duty to meet the requirements of the directive, because his workers are potentially at risk from the effects of explosions which may be produced by ignition of an ATEX which can be formed. The employer has a general obligation to provide protection to his workers potentially at risk from ATEX. In order to provide this protection, the employer shall take technical and/or organisational measures appropriate to the nature of the operation, in order of priority and in accordance with the following basic principles:

The directive indicates the different obligations which the employer shall carry out, the main of them being detailed underneath. In carrying out its obligations, the employer shall assess the specific risks arising from ATEX, taking into account at least of :

A place in which an ATEX may occur in such quantities as to require special precautions to protect the health and safety of the workers concerned is deemed to be hazardous within the meaning of this directive. The employer shall classify hazardous places where ATEX's may occur into zones on the basis of the frequency and duration of the occurrence of an ATEX and in accordance with the following definition:

The employer shall ensure that a document, hereinafter referred to as the "explosion protection document", is drawn up and kept up to date. The explosion protection document shall demonstrate in particular:

The formation of a hydrogen-air ATEX is governed by the following characteristics :

Hydrogen has explosivity characteristics which show a high reactivity:

Machinery DirectiveThis directive (2006/42/EG) applies to machinery. It shall also apply to safety components placed on the market separately. Essential safety and health requirements given in the Annex 1 of the Directive are summarised below. General requirements

Controls

Protection against mechanical hazards

Required characteristics of guards and protection devices

Protection against other hazardsMachinery must be designed and constructed by observing the following requirements.

Maintenance

Equipment and Protective Systems ... DirectiveThis Directive ("Equipment and Protective Systems intended for Use in Potentially Explosive Atmosphere", 94/9/ EC) applies to equipment and protective systems intended for use in potentially explosive atmospheres. It also applies to controlling devices and regulating devices intended for use outside potentially explosive atmospheres but required for or contributing to the safe functioning of equipment and protective systems with respect to the risks of explosion are also covered by the scope of this Directive. Essential safety and health requirements given in the Annex 2 of the Directive are summarised below. General requirements

Selection of materials

Design and constructionEquipment and protective systems must be designed and constructed:

Potential ignition sources

Hazards arising from external effects

Safety-related devicesEssential requirements are given for the safety devices, such as:

Integration of safety requirements relating to the systemEssential requirements are given related to:

Supplementary requirements in respect of equipmentGeneral requirements for equipment categories of equipment group IV are given in the table below.

Detailed requirements for each category are given in the Annex 2 of the 94/9/EC Directive. Supplementary requirements in respect of protective systems

Pressure Equipment DirectiveThe PED (Pressure Equipment Directive – 97/23/EC of the European Parliament and of the Council of 29 May 1997 on the approximation of the laws of the member States concerning pressure equipment) is applicable in Europe since December 1999 and mandatory since end of May 2002. This directive applies to the design, manufacturing and conformity assessment of pressurised equipment or assemblies with service pressure of more than 0.5 bar and a PV (Pressure water capacity) of more than 50 bar l (10 bar = 1 MPa). In the case of the hydrogen energy applications, it is particularly relevant for all pressure vessels (e. g. cylinders) and safety accessories (valves, flexible hoses, connectors) used for hydrogen refuelling station. This pressure equipment Directive allows to use everywhere in the EU the same design for the pressure vessels and associated accessories. Since this Directive is mandatory in Europe, a number of “Notified Bodies” have been notified to Brussels by the authorities of each EU member state. These notified bodies can make the “evaluation of conformity” of the pressure equipment ; this evaluation is confirmed by the “CE” mark applied onto the equipment. Any notified body (from every country) can approve a CE marked equipment to be used in every country of the EU. This Directive only defines the “essential requirements” which are given in its Annex 1. Detailed requirements are given in the harmonized standards (e.g. prepared by CEN). These EN-Standards are not mandatory, other procedures or “state of the Art” can be used by the manufacture in order to demonstrate to the notified body that the essential requirements are fulfilled. Contrary to the TPED, this European Directive doesn’t cover the use of the equipment (operational requirement, periodic inspection, …) which are still under national regulations. This may create difficulties if such equipment are to be moved from one country to another. Essential safety and health requirements given in the Annex 1 of the Directive are summarised below. General requirementsThe manufacturer has to apply the general safety principles given in the Directive. It concerns especially the risks assessment of its system. Design

Manufacturing

If appropriate, these instructions must also refer to hazards arising from misuse. Materials

Specific pressure equipment requirements

Specific quantitative requirements for certain pressure equipment

Low Voltage DirectiveFor the purposes of this Directive (73/23/EEC) "electrical equipment" means any equipment designed for use with a voltage rating of between 50 and 1,000 V for alternating current and between 75 and 1,500 V for direct current. The Annex 1 of the Directive gives principal elements of the safety objectives for electrical equipment designed for use within certain voltage limits. These requirements are described hereafter. Safety requirements

Electromagnetic Compatibility DirectiveThis Directive (89/336/EEC) applies to apparatus liable to cause electromagnetic disturbance or the performance of which is liable to be affected by such disturbance. It defines the protection requirements and inspection procedures relating thereto. The Annex 3 of the Directive gives an illustrative list of the principal protection requirements as follows:

Transport of Hazardous GoodsThe TPED (The Council Directive 1999/36/EC on transportable pressure equipment) applies to transportable pressure equipment and is mandatory since July 1st, 2003 for gas cylinders. It is also be applicable to bundles, drums and trailers. Its domain does not include fuel tanks, but only payloads. In the case of the hydrogen energy applications, it is particularly relevant for the transport of hydrogen to the filling stations. It is also applicable to H2 pressure tanks used on vehicle when these tanks are removable, refilled independently from the vehicle and transported to hydrogen depots. Like for the PED, a number of “Notified Bodies” have been notified to Brussels by the authorities of each EU member states. These Notified Bodies can make the evaluation of conformity of the pressure equipment. This evaluation is confirmed by the “P” mark applied onto the equipment. Any Notified Body (for every country) can approve a P marked equipment to be used in every country of the EU. This Directive defines the main requirements and refers to the ADR/RID for the specific requirements. ADR/RID is the transport regulation by road (ADR) and rail (RID) for Europe and many other countries around. TPED refers to “Class 2” (gases), ADR/RID covering also others dangerous substances. EN (and ISO) standards are referred into the ADR/RID and give presumption of conformity to ADR/RID but normally other routes complying with the technical requirements of ADR/RID can be followed. Contrary to the PED, TPED also covers the use of the equipment including periodic inspection and any other operational requirement. Consequently, it provides full harmonization in Europe. It also allows to “reassess” old national equipment to transform them into “P” equipment. In addition to “Notified Bodies”, “Approved Bodies” can be nominated with a restricted scope. European Regulation for Hydrogen VehiclesFollowing the 2005 decision of UNECE WP29 to develop a completely new GTR for hydrogen vehicles, the European Commission proposed a European Regulation based on the draft ECE hydrogen regulations. The European Regulation on the Type Approval of Hydrogen Powered Motor vehicles will adopt a split approach meaning that it will consist of two documents: i) The political, co-decision document will be presented for discussion and adoption by the European Parliament and the Council, including scope, reason, etc. The document: ( http://eur-lex.europa.eu/LexUriServ/site/en/com/2007/com2007_0593en01.pdf ) was adopted by the European Commission on 10 October 2007 and has now been sent to the European Parliament and Council. ii) The technical, comitology document (including technical requirements and testing procedures) is to be presented for discussion and adoption at Commission level through CATP (Committee for the Adaptation to Technical Progress). Work on this document started in January 2008. The scope of the EU Regulation includes all category M and N road vehicles, e.g. cars, buses and light/heavy duty goods vehicles. It also covers both compressed gaseous hydrogen (CGH2) and liquid hydrogen storage (LH2). The approach means that the two documents will be discussed in parallel, so some technical discussions can take place with the aim of improving the current drafts. The co-decision proposal could be adopted by the European Parliament and Council by the end of 2008/early 2009 and the aim is to have the comitology document agreed at the same time. With a 2 year transition period, the regulation could be applicable to new vehicle types by 2011 and to all vehicles by 2012. In comparison the UNECE GTR (see above) has a target adoption date of late 2010. StandardsGeneralIt is difficult to make standards for a technical field which is new and in constant development. Frequently a standard reflects a state of the art which has found to be useful by longer experience. They are of little use during the development phase of a product or technology; they may even choke the technical progress if they set too narrow margins, or they will remain ineffective. Standard makers in such a field (hydrogen and fuel cells certainly are one of them) shall restrict themselves to such provisions as will be necessary to ensure that the new product or technology can be introduced in the market easily and generally. Neither is it necessary that standardization bodies produce a lot of special standards for their field when there are already perfectly satisfactory general papers. Here an annex which deals with particular features for this application would be perfectly acceptable. The basically clear distinction between regulations and standards stated above is somewhat softened by the fact that directives and other regulations may refer to standards. If this happens the user is obliged to follow this standard, giving it a power similar to that of a regulation. But regulations usually contain some provision for the case that technical progress produces new products or applications not explicitly covered by the existing standards. These are required to meet the same safety objectives. Just the process to prove that they do is more tedious. While in the case of a conventional product the reference to the standards is enough, extensive test reports may be necessary for new ones. Certification may be done initially on an individual basis only. As soon as the new product proves that there is a market for it its manufacturers often develop appropriate standards and introduce them in the regulations. This may take time, but it is a general experience with new technologies. The link is a bit softer in case of directives of the New Approach type where references to harmonized standards are provided not as compulsory, but as a recognized way to meet the legal requirements. Details of this process are dealt with in the ISO paper “Using and Referencing ISO and IEC Standards for Technical Regulations”. Apart from public standards as those mentioned above there are also company standards and industry standards made by associations like EIGA (European Industrial Gas Association, Brussels). They have no legal status but are usually followed since they are considered as good advice on the state of the art. These general remarks should make clear that it is not feasible to ordain standardisation work or to expect a certain number of documents by a given deadline. These activities are not and can not be directed by some superior body but they depend on the free agreement of those people who make the products or activities the standards apply to. Their simple desire to create a friendly market environment usually provides sufficient driving force for the necessary standards to be published in due time. Standardisation panoramaThe focus of this report is on global or European standardisation. This is of course based on the work of the national standard bodies and the experts nominated by them. A common marketplace with common regulations also needs also common or at least harmonised standards. While ISO is doing this on a global level, there is also CEN for the domain of the EU and associated countries. A similar situation prevails with IEC and CENELEC for the field of electrotechnical standards. The following table clarifies the standardisation situation:

The Vienna agreement between ISO and CEN and between IEC and CENELEC, respectively, is to prevent duplicate work and contradictory results. It contains basically two things:

Since there is a Technical Committee on “Hydrogen Technologies” in ISO (TC 197) there is no such committee in CEN and European experts participate in the ISO working groups. Participation in ISO working groups takes place via mirror groups in national standardisation bodies. A similar situation prevails for fuel cells with IEC TC 105 “Fuel Cell Technology”. Given the global character of the technical development this is certainly appropriate. De facto CEN and CENELC will not start the drafting of hydrogen or fuel cell relevant standards anymore and leave this for international activity on ISO and IEC levels. ISOThe most important committee on standards for hydrogen technology is ISO TC 197 “Hydrogen Technologies”. ISO TC 22 SC 21 “Electric Road Vehicles” deals with fuel cell vehicles, and in future component standards for road vehicle applications will be developed by ISO TC22 SC25 “Road Vehicles Using Gaseous Fuels”. A web of cooperation agreements interlink these and many other ISO Technical Committees. Every TC has P (participating) and O (observing) members from among the national standard bodies which are members of ISO. While the O members receive all the papers and can attend the TC plenary meetings, only P members have the right to nominate experts for the working groups and to vote on the results. ISO Technical Committee 197 “Hydrogen Technologies”The secretariat is held by the Québec standardisation organisation Bureau de Normalisation du Québec (BNQ) in Canada. The membership of ISO TC 197 at the beginning of 2008 was:

The work of ISO TC 197 is organized in (at this time) thirteen working groups, but not all of them are active. Some of them have finished their task a while ago and exist only formally. Only the active ones are given in the table.

The following official documents have been published by ISO TC 197:

ISO TC 22 “Road Vehicles”ISO TC22 “Road Vehicles”is also a key hydrogen standard developer through its sub-committees SC 21 “Electric Road Vehicles” and SC 25 “Road vehicles using gaseous fuels”. The following official hydrogen related document has been published by SC21:

SC 25 is in the process of developing standards for application in road vehicles. IEC Technical Committee “Fuel Cell Technologies”The secretariat of IEC TC 105 “Fuel Cells” is held by Germany. There are currently 16 P-members and 9 O-members. Work on automotive fuel cell applications has been transferred to ISO TC22 SC21. The current situation in terms of members is like this:

The working groups are:

The following official documents have been published by IEC TC 105:

InteractionsThere are numerous interfaces between hydrogen standards and those from other fields, like pressure vessels, vehicles, etc. Work on hydrogen standards can not be done in an isolated way, but only in cooperation with the other committees. ISO TC 197 and IEC TC 105 have a liaison with each other. ISO TC 197 has other liaisons with ten ISO TCs and a few sub-committees, plus other liaisons with external bodies as the European Hydrogen Association and the National Hydrogen Association (USA). The situation is similar for IEC TC 105. Recent ProgressRecent ProgressAt the time of writing this report we find that hydrogen energy and fuel cells become increasingly important in economical and also political terms. Those who make regulations and standards see this and increase their activity. IEC TC 105 has meanwhile produced a lot of urgently needed papers and will continue to do so. ISO TC 197 is in a similar situation. In terms of legal requirements the sector which needs the greatest attention is hydrogen as fuel for road vehicles and the associated infrastructure. For the reasons explained above in detail a global regulation is not available and will not be for a while. So the European Commission has submitted a draft for the political part of an European Regulation for the type approval of hydrogen cars. However, the EU Regulation is expected to come into force in 2011/2012 at around the same time that the UNECE GTR is planned to be adopted. HySafe as well has sent a position paper on the original draft to the EC. The EC funded project HyApproval works on the establishment of a Handbook for the approval of hydrogen refuelling stations for road vehicles, first in Europe but due to its international partners also coordinated with the leading world markets (China, Japan, USA). The important and difficult thing with a document on a field developing as rapidly as this is to make it specific enough to meet its purpose while at the same time not to make it so specific that it restrains technical progress. Since national regulations in some countries make it practically impossible to put a hydrogen car on public roads the intended regulation is in principle highly desirable. Some common guide on approving filling stations would also be of help, though here the national regulations have a greater weight. Since December 2007, the HyApproval Handbook is available for download at:

Appendix V will become available in the first half of 2008. List of some Useful Guidelines and Documents

<< | Content | >> |